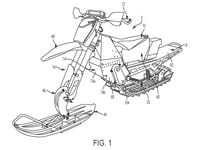

The purpose-built machine takes the Timbersled idea to the next level.

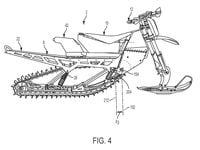

For more than a decade Timbersled has been manufacturing kits to convert dirt bikes into snow bikes with a design that replaces the front wheel with a ski and the rear with a track. After Timbersled was taken over by Polaris in 2015, it seems that the same technology is now being developed into a purpose-made machine. A newly published patent from Polaris, penned by Timbersled founder Allen Mangnum, is the latest in a series of documents relating to the design, which adopts the same tracked rear drive system and fork-based front suspension as existing Timbersled kits but adds them to a purpose-made central chassis section instead of a normal motocross bike.

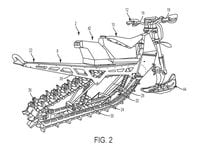

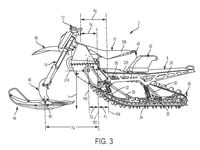

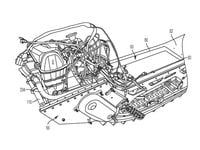

Unusually, the chassis is a unibody design, with aluminum panels bolted to either side of a Husqvarna 450 single-cylinder engine to form the main structure. The design allows the engine to be mounted higher and further forward than it would be in a motorcycle frame, tucking it right behind the steering head. As a result, the entire layout of the bike is changed.

On a normal snow bike that’s converted from a motorcycle, the driving wheel of the rear track is forced to be relatively far back, behind the swingarm pivot of the motorcycle frame. That means it’s also behind the main section of the seat and the footpegs, so the rider’s weight isn’t directly over it. On the new design, the track’s drive wheel is much further forward, putting the rider directly above the track and making for a shorter vehicle overall.

RELATED: 2017 Timbersled Snow Bike FIRST RIDE Review

Both the tracked rear suspension and the front fork systems are basically the same as the ones in current Timbersled conversion kits, but the purpose-made chassis has also allowed for tweaks to the rear end’s geometry. Those changes increase the suspension travel from around 9 inches to a full 12 inches at the back.

With the engine moved forward and up, the fuel tank is also repositioned, shifting to the space that’s now freed up directly under the rider’s seat. The cooling, meanwhile, is achieved by running water from the engine into a heat exchanger above the track, as on many snowmobiles, instead of a radiator. Snow, water, and ice thrown up by the track hit the heat exchanger to help transfer heat away from the water inside it.

Tracing the paper trail from the new Polaris patent shows that the project has been under development since at least 2018, and it’s clearly something that’s still being worked on at the moment so a production machine based on these ideas might not be far away.